At Importaco, food quality is much more than a regulatory requirement: it is a daily commitment to continuous improvement, food safety and the trust of the people who consume our products.

That is why we have developed Importaco’s 360º Quality Model, a comprehensive approach that connects all areas of the organisation around a shared goal: to guarantee safe, nutritious, healthy food produced in a sustainable way.

This model brings together scientific knowledge, technological innovation and advanced data management, ensuring traceability, operational excellence and quality control at every stage of the food value chain, from origin to the final consumer.

What does the 360º Quality Model consist of?

Importaco’s 360º Quality Model is structured around four complementary dimensions that enable quality to be managed in a holistic, preventive and future-oriented way:

- · Corrective quality

- · Preventive quality

- · Exploratory quality

- · Predictive quality

Each dimension provides specific value to strengthen food safety, innovation, process efficiency and sustainability.

Corrective quality: continuous improvement and process control

Corrective quality focuses on the analysis and continuous improvement of our production processes, based on internal controls and feedback received from customers.

At Importaco, we use state-of-the-art monitoring technology to ensure the reliability and specialisation of each production line. Every year, our products are analysed against more than 150 quality parameters, 25% of which are directly related to food safety.

In addition, our teams systematically manage customer audits and recommendations, turning them into improvement actions that reinforce product quality and trust in the brand.

Preventive quality: food safety from the source

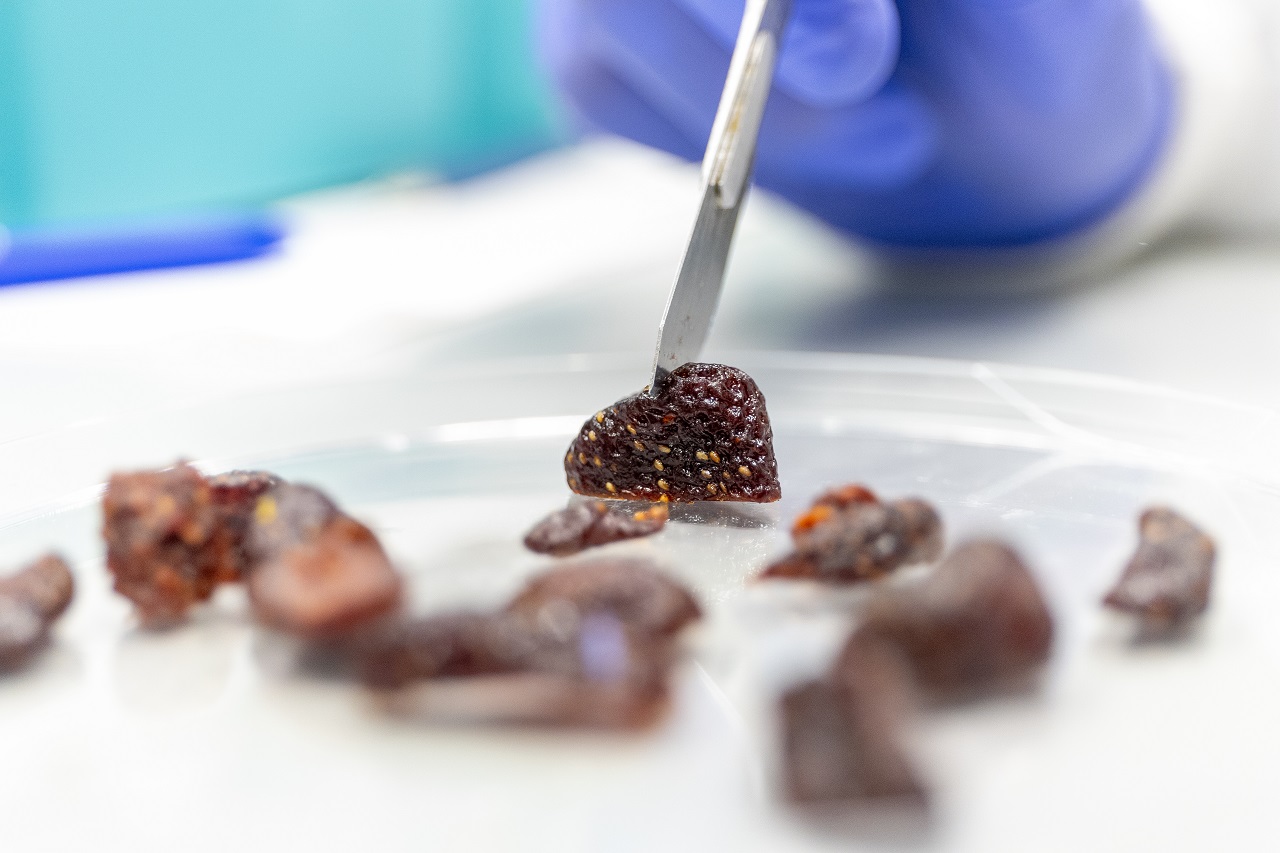

Preventive quality is a fundamental pillar of our model. We apply rigorous quality and food safety protocols across all stages of the value chain, anticipating potential risks.

Through initiatives such as Agricultural Integration and Quality at Origin, we work closely with farmers and suppliers to guarantee food traceability from field to consumer. This collaborative approach encourages knowledge sharing, best practices and more sustainable production.

Our processes are certified under international standards such as the BRC Global Standard for Food Safety and IFS Food, and also hold kosher and halal certifications, confirming compliance with the most demanding requirements in the food industry.

Exploratory quality: innovation applied to food

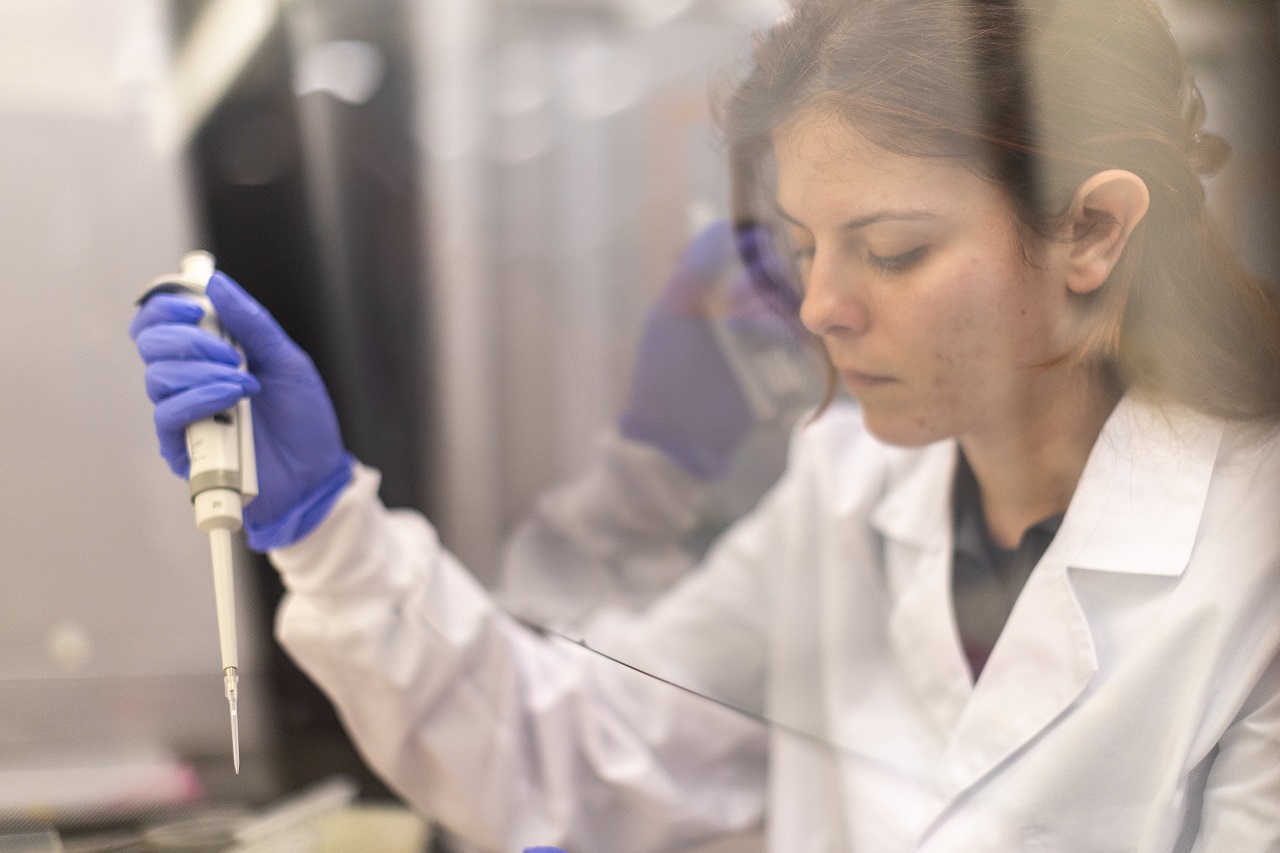

Exploratory quality drives innovation as a lever for improvement. At Importaco, we research new technologies and develop open innovation projects together with technology centres, universities and start-ups.

This approach allows us to analyse technologies that are already well established in other sectors and adapt them to the food industry, delivering innovative solutions to challenges related to food safety, sustainability and production efficiency.

Predictive quality: anticipation and data analysis

Predictive quality represents the most advanced stage of our quality management model. By using online and at-line data intelligence, together with multivariate analysis techniques, we are able to anticipate deviations and product behaviour.

We prepare process reports and trend analyses on critical quality characteristics, while our quality cells monitor production in real time. This system reduces the risk of incidents and strengthens precision and reliability at every production stage.

A quality model focused on people and the planet

Importaco’s 360º Quality Model reflects our vision of holistic quality, connecting people, processes and scientific knowledge to deliver products that contribute to people’s wellbeing and respect for the planet.

We therefore reaffirm our commitment to continuous improvement, responsible innovation and operational excellence — pillars that drive us to keep building a safer, more sustainable and healthier future.